Plastic PE/PP/HDPE/LDPE/LLDPE/BOPP Film/Bag/Woven Bag/Non Woven/Fiber/Granulating Line/Granulation Plant/Agglomeration Recycling/Compact Pelletizing Machine

Basic Info.

| Model NO. | TSSJ100~200 THSJ65~220 TCSJ85~180 TCDJ85~180 |

| Plastic Type | HDPE LDPE LLDPE PP Film |

| Screw | Single-Screw |

| Automation | Automation |

| Computerized | Customized |

| Certification | ISO9001:2008, CE |

| After-Sale Service | Engineers Available to Service Machinery Overseas |

| Feeder Type | Force Feeder or Compactor |

| Stage | Doulbe or Single or Multi |

| Type of Extruder | Deagassing Tyep |

| Color | Could Be Customized |

| Transport Package | Wrap Film |

| Specification | TSSJ100~200 THSJ65~220 TCSJ85~180 TCDJ85~180 |

| Trademark | RETECH |

| Origin | China |

| HS Code | 8477201000 |

| Production Capacity | 200~1000kg/H |

Packaging & Delivery

Package Size 1500.00cm * 500.00cm * 500.00cm Package Gross Weight 12000.000kgProduct Description

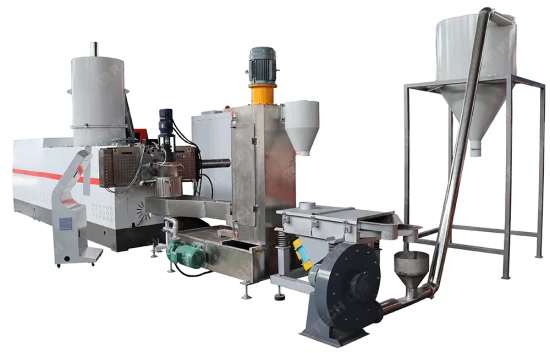

Plastic PE/PP/HDPE/LDPE/LLDPE/BOPP Film/Bag/Woven Bag/Non Woven/Fiber/Granulating Line/Granulation Plant/Agglomeration Recycling/Compact Pelletizing Machine Product DescriptionRCSJ Series Plastic PP PE film 3 in 1 function compactor pelletizing machine is working to reprocessing kinds of plastic LDPE/HDPE film,such as HDPE bag leftover material,useless plastic shopping bag/film,logistic LLDPE wrapping packaging film,etc.Our LDPE LLDPE HDPE BOPP film compactor pelletizing line is designed and manufactured by RETECH team,it combines the latest new Euro recycling tech which with function of cutting/compacting/pelletizing the plastic film in one step,the specially designed structure screw ensure the best extrusion and vacuum degassing performance.Application:PE/LDPE/LLDPE/HDPE/BOPP film granulating linePP yarn/PP woven bag/PP jumbo bag/PP silk/PP fiber pelletizing machinePS/EPS/XPS/EPE foam recycling line

| No. | Name | Pictures |

| 1 | Belt conveyor with metal detectorFunction: It applies the latest multiple-frequency detection technology, the material effect automaticeliminating technology, the automatic balance technology and self-adaptive adjustmenttechnology, which render the simplest operation, best environment suitability andstrongest stability of the equipment in the industry. As the product has the unique one-touch automatic setup function, it may automatically adjust to the best detecting state forproducts passing the detecting area for only once, in realization of simplify operation. | |

| 2 | CompactorFunction: The rotatory blades of compactor will cut up incoming scraps. Frictional heating whichcaused by high speed rotatory blades will heat and let scraps shrinking just below theiragglomerating point. Optimal designed guide structure compacts the material and directsit into extruder screw. Crushes, dries and compacts the material which enables a fastand stable feeding from the compactor directly into the extruder. | |

| 3 | RCSJ130/33 main extruderFunction: A specialized single screw extruder applied to gently melt the pre-compacted material.The plastic scraps will be well melted, plasticized in the first stage extruder, and theplastic will be extrude by the second stage extruder. With double-zone vacuumdegassing system, volatiles such as low molecular and moisture will be removedefficiency, especially suitable to heavy printed film and material with some water content. | |

| 4 | Hydrualic screen exchangerFunction:Piston Filters with Large Filtration Area:l Very large filtration area,up to 3,000 cm² for standard products,and larger onesup to 10,000 cm² model are also availablel Reducing screen changing frequency,improved productivityl Built-in static mixer improving product stabilityl Superior sealing system completely eliminating polymer leakagel Very low operation cost | |

| 6 | Die face cutting systemFunction:Adjust the pelletizer speed automatically based on the pressure of Die head, andachieve the uniform final pellets size.Pneumatic blade clamping device: knife of pelletizing system compact with Die headautomatically by pneumatic system, in order to achieve 100% contact between theblade and the pelletizing template , enhanced concentricity of blade, and slow itsabrasion time. |

Detailed picture of PP PE film compactor pelletizing machine:

| Model | Diameter of screw | PE capacity | PP capacity |

| RCDJ-85 | Φ85mm | 150-200kg/h | 100-150kg/h |

| RCSJ-85/85 | Φ85/85mm | 150-200kg/h | 100-150kg/h |

| RCDJ-100 | Φ100mm | 280-350kg/h | 250-300kg/h |

| RCSJ-100/100 | Φ100/100mm | 280-350kg/h | 250-300kg/h |

| TCDJ-130 | Φ130mm | 480-550kg/h | 400-500kg/h |

| RCSJ-130/130 | Φ130/130mm | 480-550kg/h | 400-500kg/h |

| RCDJ-160 | Φ160mm | 650-800kg/h | 600-750kg/h |

| RCSJ-160/160 | Φ160/160mm | 650-800kg/h | 600-750kg/h |

| RCDJ-180 | Φ180mm | 800-1200kg/h | 750-1000kg/h |

| RCSJ-180/180 | Φ180/180mm | 800-1200kg/h | 750-1000kg/h |